- Home

- Products

- Services

- Product concept development

- Engineering

- Design for manufacturability

- Regulatory services

Read more - Material selection and formulation

- Prototyping

- Testing and validation

Read more - Production process development

- Custom tooling

- Manufacturing

- Finishing operations

- Assembly

- Packaging

- Private labeling

- Sterilization

Read more

- Resources

- Careers

- Search

7 Essential Benefits of Using Peelable Heat Shrink Tubing in Your Operations

In today's fast-paced industrial landscape, choosing the right materials for insulation and protection of wires and cables is crucial. Among the various options available, Peelable Heat Shrink Tubing stands out as a versatile and efficient solution. This innovative product offers unique benefits that can significantly enhance operational efficiency, reduce downtime, and improve overall performance. Understanding the advantages of using Peelable Heat Shrink Tubing can help businesses make informed decisions that bolster their processes and safeguard their investments.

The growing demand for reliable insulation solutions has led to the increased popularity of Peelable Heat Shrink Tubing across various industries. This specially designed tubing not only provides robust protection against environmental factors but is also easy to apply and remove, making it a preferred choice for many applications. In this blog, we will explore seven essential benefits of using Peelable Heat Shrink Tubing in your operations, highlighting how incorporating this innovative material can lead to improved safety, cost-effectiveness, and increased productivity.

Understanding Peelable Heat Shrink Tubing: A Comprehensive Overview

Peelable heat shrink tubing is gaining traction in various industries due to its unique properties and practical applications. This specialized tubing, designed for easy removal after installation, offers considerable advantages over standard heat shrink options. According to a report by Smithers Pira, the global market for heat shrink tubing is projected to reach $2.4 billion by 2025, highlighting the growing demand for versatile solutions like peelable heat shrink tubing in electrical and industrial sectors. One of the most significant benefits of peelable heat shrink tubing is its ability to streamline maintenance operations. When repairs or modifications are necessary, peelable tubing can be swiftly removed without damaging the underlying wiring or components. This is particularly beneficial in industries such as aerospace and automotive, where down-time can result in substantial financial losses. A study by TechNavio found that efficient maintenance practices can decrease operational costs by up to 20%. Moreover, peelable heat shrink tubing provides enhanced protection against environmental factors such as moisture, dust, and chemicals. A report from MarketsandMarkets indicates that the demand for tubing with superior protective qualities is increasing, driven by the need for reliable and long-lasting solutions in harsh operating conditions. By utilizing peelable heat shrink tubing, companies can ensure that their components maintain optimal performance while also preserving the integrity of their installations, a crucial factor in safety-critical applications.

Key Advantages of Using Peelable Heat Shrink Tubing in Industrial Applications

Peelable heat shrink tubing offers numerous advantages in industrial applications, making it a valuable choice for various operations. One of the primary benefits of using this specialized tubing is its ease of application. Unlike traditional heat shrink options that require precision and care during installation, peelable tubing can be applied more quickly and efficiently. Once heat is applied, it forms a tight seal while still allowing for easy removal, which can be particularly beneficial when repairs or modifications are needed.

Another key advantage lies in its protective features. Peelable heat shrink tubing is designed to safeguard sensitive components from environmental factors such as moisture, dust, and abrasion. This added layer of defense is crucial in demanding settings where exposure to harsh conditions can lead to failures or costly downtimes. The tubing’s robust material not only enhances durability but also provides a professional finish that can enhance the overall quality of an assembly.

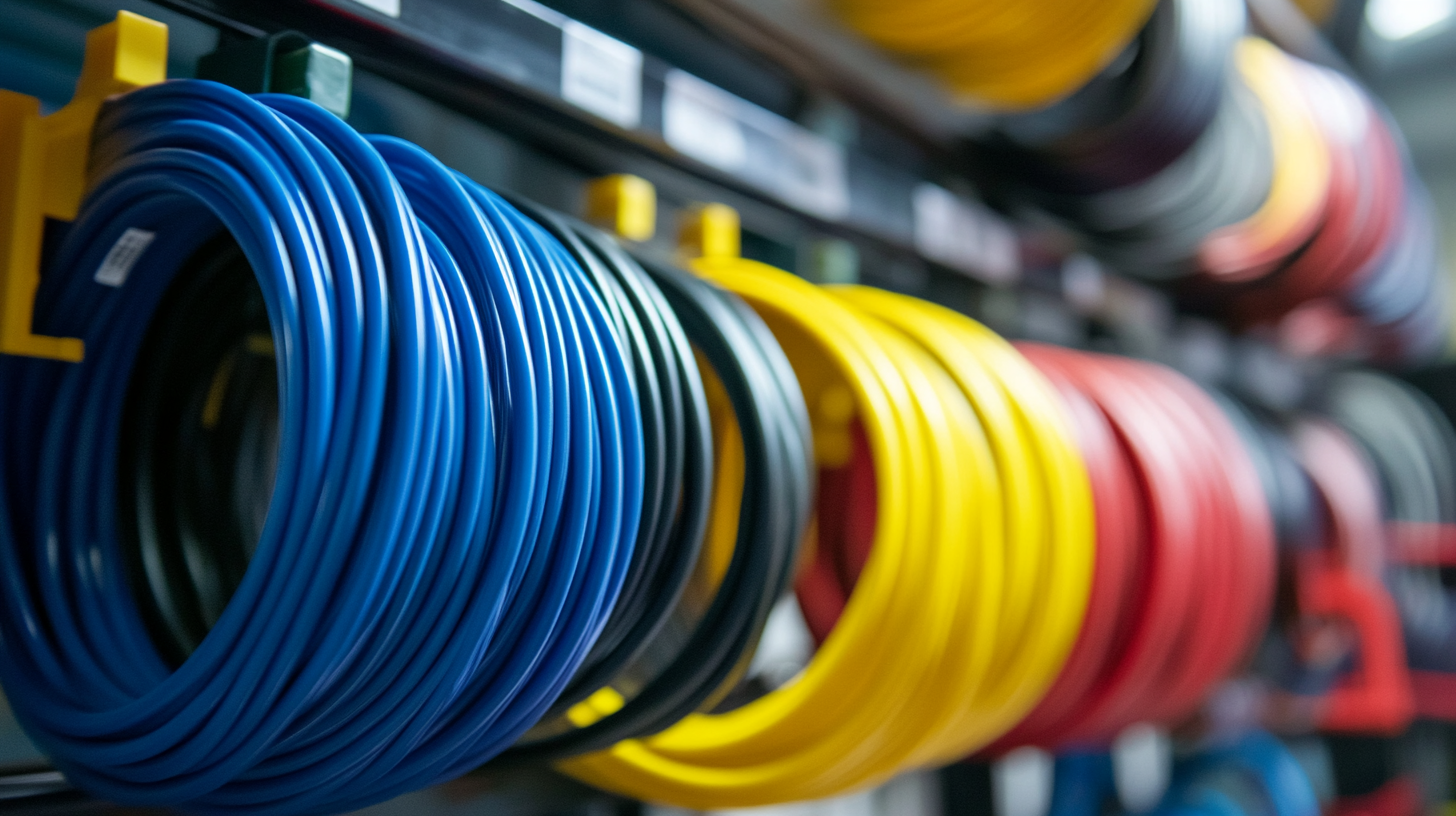

Furthermore, peelable heat shrink tubing is highly versatile, available in various sizes and colors, which allows for optimal customization in industrial projects. Whether used for wire harnesses, cable management, or electronic insulation, this tubing meets diverse operational needs. Its ability to maintain functionality while offering aesthetic appeal ensures that it can be integrated seamlessly into any application, reinforcing the importance of using peelable heat shrink tubing in today’s industrial environments.

Enhanced Safety and Protection: How Peelable Tubing Safeguards Components

Peelable heat shrink tubing is becoming increasingly popular in various industries due to its enhanced safety and protection capabilities. This specialized tubing is designed to provide a reliable and effective barrier against environmental factors, ensuring that critical components remain safe and functioning optimally. By using peelable heat shrink tubing, operators can significantly reduce the risk of damage caused by moisture, dust, and other contaminants that can lead to equipment failure.

One of the primary benefits of peelable tubing is its ability to be easily removed without causing harm to the underlying components. This feature allows for efficient maintenance and inspections, ensuring that any necessary adjustments or repairs can be made promptly. Moreover, the tubing is often designed with exceptional clarity, making it easier for technicians to visually check connections and components without needing to remove the protective layer every time. This not only enhances safety but also increases productivity in operations where time is of the essence.

Furthermore, peelable heat shrink tubing is often made from materials that exhibit excellent electrical insulating properties. This is crucial in preventing short circuits and other electrical failures that can pose serious safety risks. By utilizing this type of tubing, businesses can enhance the overall safety of their operations, protecting both personnel and equipment from potential hazards. In summary, peelable heat shrink tubing stands out as an essential solution for safeguarding components, making it a valuable addition to any operational workflow.

Cost-Effectiveness of Peelable Heat Shrink Tubing for Long-Term Operations

Peelable heat shrink tubing has emerged as a cost-effective solution for various operations, offering significant advantages that enhance both efficiency and budgeting. According to a report from the Freedonia Group, the demand for heat shrink tubing is projected to grow by 5.6% annually, highlighting its increasing relevance in industries where effective insulation and protection of cables are paramount. The peelable feature allows for easy application and removal, reducing labor costs associated with installation and maintenance.

In long-term operations, the cost-effectiveness of peelable heat shrink tubing becomes even more apparent. The ability to quickly access and replace components without the need for excessive labor can lead to considerable savings over time. For instance, a case study from IPC shows that companies utilizing peelable tubing reported a 30% decrease in downtime during equipment servicing. By minimizing the time spent on maintenance, organizations can significantly enhance productivity metrics, ultimately leading to better profit margins.

Another layer of financial efficiency stems from the reduced material costs associated with peelable heat shrink tubing. A study by MarketsandMarkets indicates that innovations in materials used in heat shrink products lead to lower manufacturing costs, which translates to direct savings for end-users. These savings, combined with the longevity and durability of high-quality peelable tubing, make it a financially wise choice for companies aiming to streamline their operations while maintaining quality and safety standards.

Versatility of Peelable Heat Shrink Tubing Across Different Industries

Peelable heat shrink tubing (PHST) has emerged as a game-changing solution across various industries, owing to its exceptional versatility and functionality. This tubing is particularly significant for the medical sector, as highlighted by recent advancements specifically tailored for catheter manufacturers. The latest development features a 1.8:1 shrink ratio in a translucent format, which allows for enhanced precision when it comes to intricate bonding and welding applications. This is crucial not only for ensuring the integrity of the product but also for facilitating more complex medical device designs.

According to market research, the global heat shrink tubing market is expected to reach approximately $3.3 billion by 2025, driven by increasing demand in the medical and automotive industries. As manufacturers seek solutions that provide reliable protection and adaptability, PHST offers unique benefits that traditional tubing cannot match. Its peelable nature means that it can be easily removed without damaging the underlying components, making it ideal for applications where maintenance or replacement is necessary.

Moreover, the versatility of peelable heat shrink tubing extends to various sectors such as electronics, telecommunications, and automotive. In these industries, the need for reliable insulation, strain relief, and environmental protection is critical, and PHST meets these requirements with its robust features. The growing trend towards miniaturization in devices also demands solutions that can cater to tight spaces while offering performance and safety, where PHST truly excels.