- Home

- Products

- Services

- Product concept development

- Engineering

- Design for manufacturability

- Regulatory services

Read more - Material selection and formulation

- Prototyping

- Testing and validation

Read more - Production process development

- Custom tooling

- Manufacturing

- Finishing operations

- Assembly

- Packaging

- Private labeling

- Sterilization

Read more

- Resources

- Careers

- Search

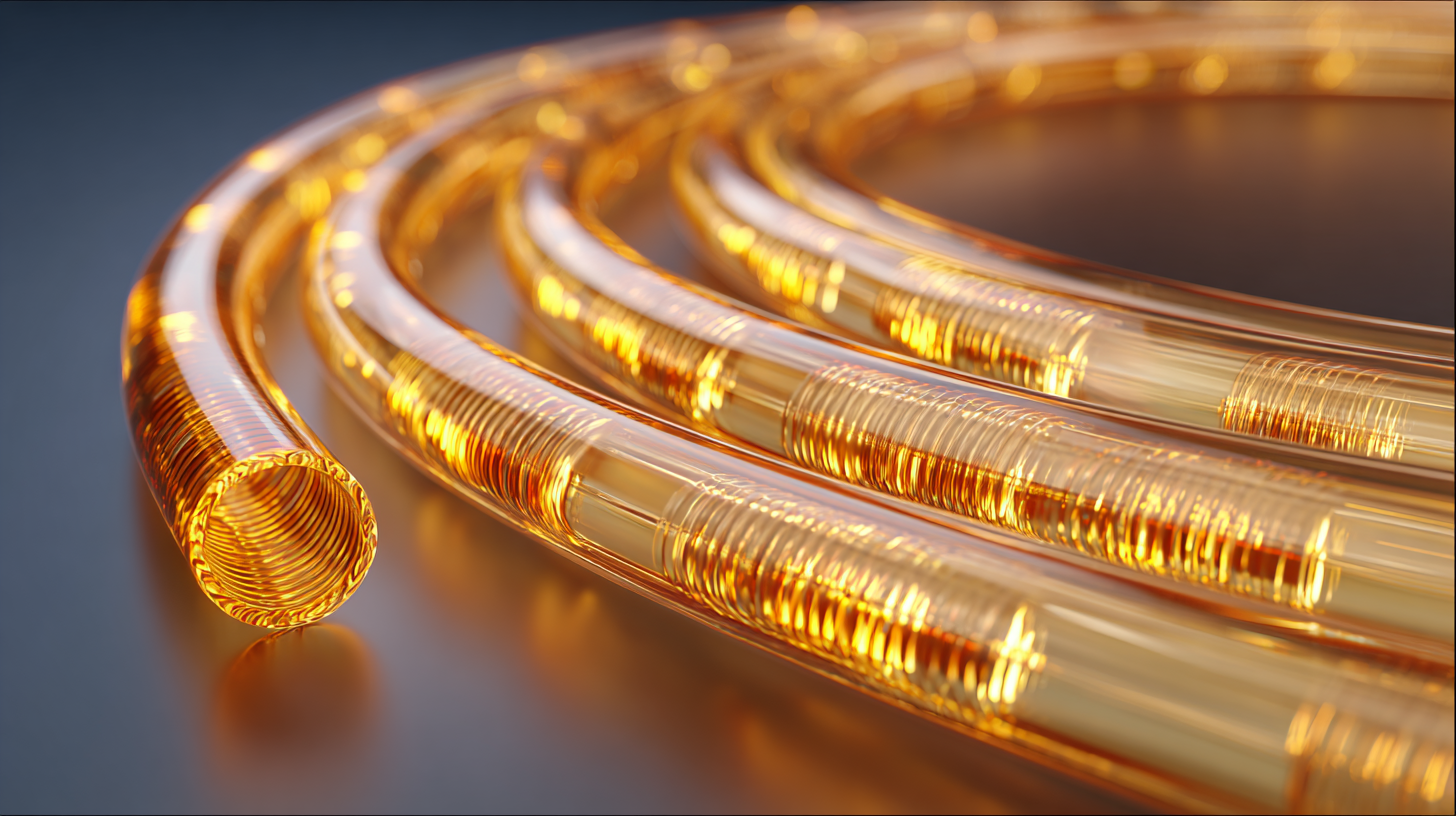

What is Polyimide Tubing? Unveiling Properties, Applications, and Market Trends in 2023

Polyimide tubing has emerged as a critical material in various high-performance applications, showcasing unique properties such as exceptional thermal resistance and chemical stability. According to a report by MarketsandMarkets, the polyimide market is projected to reach USD 3.75 billion by 2025, growing at a CAGR of 8.7% from 2020 to 2025, reflecting an increasing demand across industries such as aerospace, electronics, and automotive.

With its ability to withstand extreme temperatures and harsh environments, polyimide tubing is particularly sought after for insulating and protecting sensitive components. As the demand for advanced materials rises, understanding the distinctive properties and diverse applications of polyimide tubing becomes essential for manufacturers and engineers looking to optimize performance and innovation in their respective fields. This blog delves into the critical aspects of polyimide tubing, exploring its properties, applications, and emerging market trends in 2023.

With its ability to withstand extreme temperatures and harsh environments, polyimide tubing is particularly sought after for insulating and protecting sensitive components. As the demand for advanced materials rises, understanding the distinctive properties and diverse applications of polyimide tubing becomes essential for manufacturers and engineers looking to optimize performance and innovation in their respective fields. This blog delves into the critical aspects of polyimide tubing, exploring its properties, applications, and emerging market trends in 2023.

Understanding Polyimide Tubing: Definition and Key Features

Polyimide tubing is a remarkable material known for its exceptional thermal stability and chemical resistance. Defined as a type of polymer that maintains its strength and integrity at elevated temperatures, polyimide tubing can withstand continuous exposure to temperatures ranging from -200°C to over 300°C. This unique characteristic makes it a preferred choice for a variety of demanding applications, particularly in industries such as aerospace, automotive, and electronics.

Key features of polyimide tubing include not only its temperature resilience but also its outstanding dielectric properties, making it an excellent insulator for electrical components. Additionally, the tubing is inherently flexible yet robust, allowing it to be easily manipulated while retaining its shape and durability. Its resistance to a wide array of chemicals adds to its versatility, enabling use in environments where other materials might fail. As technological advancements continue to progress, the application range for polyimide tubing is expected to expand further, reflecting its critical role in engineering innovative solutions across multiple sectors.

Polyimide Tubing Market Analysis 2023

This chart illustrates the projected growth in demand for polyimide tubing across various industries in 2023, highlighting the sectors with the highest utilization rates.

Comparing Polyimide Tubing to Other High-Performance Materials

Polyimide tubing stands out in the realm of high-performance materials due to its exceptional thermal stability and chemical resistance. When compared to alternatives such as PTFE (Teflon) and PEEK, polyimide demonstrates superior thermal endurance, with operating temperatures reaching up to 260°C (500°F) continuously, as indicated by the 2022 Material Research Report. This property makes polyimide an ideal choice for applications in aerospace, electronics, and automotive industries, where exposure to extreme conditions is common.

Moreover, polyimide tubing offers enhanced mechanical strength and flexibility versus conventional materials. According to a recent study published in the Journal of Polymer Science, polyimide's tensile strength can reach upwards of 70 MPa, outperforming PTFE and PEEK in various stress conditions. Additionally, its ability to maintain dimensional stability in high-temperature environments gives it an edge in precision applications, such as in semiconductor manufacturing, where maintaining exact specifications is critical. In an increasingly competitive market, the demand for polyimide tubing is projected to grow at a CAGR of 8.4% from 2023 to 2030, emphasizing its role in advancing technology and material science.

Exploring the Applications of Polyimide Tubing Across Industries

Polyimide tubing has emerged as a crucial component across various industries due to its exceptional thermal and chemical resistance. This unique material is especially favored in aerospace, automotive, and electronics sectors, where standard materials may fail under extreme conditions. In aerospace applications, for instance, polyimide tubing is utilized in insulation systems and fuel lines, ensuring reliable performance even in high-temperature environments. Its lightweight yet durable nature contributes to enhanced efficiency and safety in aircraft components.

In the electronics industry, polyimide tubing serves a vital role in circuit boards and connectors, providing insulation that withstands thermal stress and harsh chemicals. With the increasing miniaturization of electronic devices, the demand for thin-walled, flexible tubing has skyrocketed. Additionally, its application in medical devices, such as catheters and guide wires, has gained traction due to biocompatibility and sterilization capabilities. As industries continue to innovate, polyimide tubing is poised to be a key player, driving advancements with its versatile properties.

Current Market Trends for Polyimide Tubing: Insights and Predictions

Polyimide tubing, known for its exceptional thermal and chemical resistance, has recently gained significant traction across various industries. In 2023, the demand for polyimide tubing is increasingly driven by its applications in flexible printed circuits and specialty fabricated products. As per market analysis, the polyimide film market is poised for substantial growth, reflecting a broader trend where industries are moving towards advanced materials that enhance performance and durability.

Current market insights suggest that the global market for polyimide tubing is part of a flourishing landscape, with the overall polyamide resin market projected to exhibit a CAGR of approximately 3.90% from 2025 to 2034. This upward trajectory is indicative of an increasing preference for lightweight and high-strength materials in automotive and aerospace sectors. As businesses look to innovate, polyimide’s remarkable properties are expected to solidify its presence in high-performance applications.

**Tips:** When selecting polyimide tubing for specific projects, consider both the thermal and mechanical requirements of your application to ensure optimal performance. Additionally, keep an eye on emerging market trends, as they can provide valuable insights into the future availability and pricing of these advanced materials. Regularly reviewing industry reports can also help you stay informed about competitor strategies and innovations.

What is Polyimide Tubing? Unveiling Properties, Applications, and Market Trends in 2023

| Property | Value | Application | Market Trend |

|---|---|---|---|

| Temperature Resistance | -269°C to 260°C | Aerospace and Defense | Growing demand for lightweight materials |

| Chemical Resistance | Excellent | Electronics and Semiconductor | Increasing use in advanced electronic designs |

| Dielectric Strength | High | Medical Devices | Rising demand in medical technology |

| Flexibility | Good | Automotive | Trend towards more efficient automotive systems |

| Lightweight | Yes | Industrial Applications | Increasing focus on reducing overall system weight |

Future Innovations in Polyimide Tubing: What to Expect in the Coming Years

As we look ahead into the future of polyimide tubing, several key innovations are expected to shape its development and applications in various industries. Recent research indicates that the polyimide market is projected to grow significantly, with a CAGR of over 7% between 2022 and 2028, reaching an estimated value of approximately $1.74 billion by 2028 (Market Research Future). This growth is driven by the increasing demand for lightweight and durable materials in aerospace, automotive, and electronics sectors, where polyimide’s superior temperature resistance and mechanical properties are crucial.

Emerging trends suggest that advancements in manufacturing technologies, such as additive manufacturing and enhanced processing techniques, will enable the production of polyimide tubing with improved properties and performance. A report from Grand View Research highlights that advancements in polymer chemistry are paving the way for new formulations that enhance thermal stability and reduce production costs. As innovation accelerates, we can expect polyimide tubing to play a pivotal role in high-efficiency applications, including medical devices and flexible electronics, leading to more robust performance in extreme conditions.