- Home

- Products

- Services

- Product concept development

- Engineering

- Design for manufacturability

- Regulatory services

Read more - Material selection and formulation

- Prototyping

- Testing and validation

Read more - Production process development

- Custom tooling

- Manufacturing

- Finishing operations

- Assembly

- Packaging

- Private labeling

- Sterilization

Read more

- Resources

- Careers

- Search

Essential Tips for Identifying Reliable Suppliers of PGA Sutures

In the fast-evolving field of medical sutures, the demand for biocompatible and efficient materials is higher than ever, particularly for PGA sutures. According to a recent report by MarketsandMarkets, the global surgical sutures market is projected to grow from $4.16 billion in 2020 to $6.15 billion by 2025, at a compound annual growth rate (CAGR) of 8.1%. Among the various types of sutures, polyglycolic acid (PGA) sutures are gaining significant traction due to their superior absorption properties and minimal inflammatory responses. This surge in demand illustrates the critical importance of sourcing reliable suppliers that can meet the stringent quality requirements of healthcare institutions.

Identifying trustworthy suppliers of PGA sutures is essential not only for ensuring the safety and efficacy of surgical procedures but also for maintaining compliance with regulatory standards. A comprehensive study by Grand View Research highlights that quality control measures in the manufacturing process must adhere to international standards, including ISO certifications and FDA approvals. As surgical procedures become increasingly complex, the choice of sutures directly impacts patient outcomes. Therefore, healthcare providers must equip themselves with essential strategies to discern reliable suppliers who can consistently deliver high-quality PGA sutures, thereby contributing to improved surgical success rates and patient satisfaction.

Understanding the Importance of Reliable Suppliers in Surgical Supply Chains

In the complex framework of surgical supply chains, identifying reliable suppliers of PGA sutures is not just a matter of procurement; it’s critical for ensuring patient safety and effective care. Reliable suppliers play a pivotal role in providing high-quality materials that are essential to successful surgical outcomes. Recent reports from healthcare experts indicate that disruptions in the supply chain can significantly impact the delivery of care, highlighting the necessity of vetting suppliers meticulously. The importance of a resilient supply chain is further underscored by recent policy interventions aimed at reducing prescription drug shortages. These strategies include forming large-scale public-private partnerships, which have proven essential in not only maintaining the availability of surgical supplies but also in enhancing the overall resilience of healthcare systems. A study revealed that effective supply chain management can lead to a 20% reduction in operational costs while improving service delivery, thereby emphasizing the value of collaborating with trustworthy suppliers who can meet stringent regulatory standards. Intermountain Healthcare exemplifies how proactive preparation and creative problem-solving can fortify supply chain resilience, particularly during crises like the pandemic. Their approach not only safeguarded their supply lines for critical surgical products, including sutures, but also reinforced the importance of establishing partnerships with reliable suppliers. As the healthcare sector continues to confront challenges, it is imperative that surgical supply chains prioritize relationships with vetted suppliers who can ensure a consistent flow of high-quality PGA sutures, thus protecting patient safety and upholding healthcare standards.

Key Characteristics to Look for in Competent PGA Suture Suppliers

When sourcing PGA sutures, it is essential to identify suppliers that exhibit key characteristics indicative of reliability and competence. First and foremost, certification and compliance with industry standards are critical markers. Suppliers should possess certifications such as ISO 13485, which demonstrates adherence to quality management systems specific to medical devices. According to a recent industry report, approximately 75% of credible suppliers have such certifications, ensuring that they meet the rigorous safety and effectiveness requirements necessary for PGA sutures.

Another vital factor to consider is the supplier's experience and reputation within the medical community. A reliable supplier should have a proven track record, reflected in customer testimonials and case studies. The latest data suggests that suppliers with over 10 years in the market have a significantly lower rate of product recalls and complaints. This experience often translates into better product innovation, with 62% of established suppliers actively investing in research and development to enhance their product offerings.

Moreover, transparency in sourcing and production processes is increasingly becoming an expectation. Suppliers who openly disclose their materials' sourcing and manufacturing conditions tend to foster greater trust among healthcare providers. Reports indicate that 80% of healthcare professionals prefer suppliers that provide full transparency about their production practices, especially for products like PGA sutures that are vital for patient outcomes.

In summary, focusing on certification, experience, and transparency when evaluating potential suppliers will greatly aid healthcare providers in securing high-quality PGA sutures that are both effective and safe for patient care.

Evaluating Supplier Certifications and Regulatory Compliance

When evaluating suppliers of PGA sutures, understanding their certifications and regulatory compliance is paramount. The landscape of supplier evaluation is increasingly shaped by regulatory requirements, such as those proposed by the Department of Defense regarding contractor cybersecurity. Compliance with such standards not only ensures that suppliers meet the necessary security protocols but also reflects their overall commitment to quality and reliability in their products.

Integrating a robust Quality Management System (QMS) is an essential step in assessing supplier capabilities. QMS software solutions aid organizations in maintaining high standards of quality and compliance while enhancing communication among teams. By leveraging these tools, companies can systematically evaluate suppliers against established benchmarks, ensuring that they adhere to both industry standards and regulatory mandates. Such diligence in verification helps businesses mitigate risks associated with supplier selection.

Additionally, given the rising importance of Environmental, Social, and Governance (ESG) considerations, a comprehensive supplier assessment now extends beyond mere compliance checks. Organizations are shifting towards dynamic, ongoing monitoring of their supply chains to address ESG risks effectively. This approach not only fosters responsible sourcing practices but also enhances the resilience of the supply chain by ensuring that all suppliers align with ethical and environmental standards. By prioritizing these factors, businesses can confidently select suppliers who not only provide high-quality products but also uphold essential ethical values.

Assessing Quality Control Processes for PGA Sutures

When evaluating suppliers of PGA sutures, assessing their quality control processes is critical to ensuring the reliability and effectiveness of the products. A comprehensive quality control system should include rigorous testing methods, traceability, and compliance with international standards such as ISO 13485. According to a recent report by Market Research Future, the global market for absorbable sutures, including PGA sutures, is projected to grow at a CAGR of 6.2% through 2027, highlighting the necessity for stringent quality assurance in supplier selection.

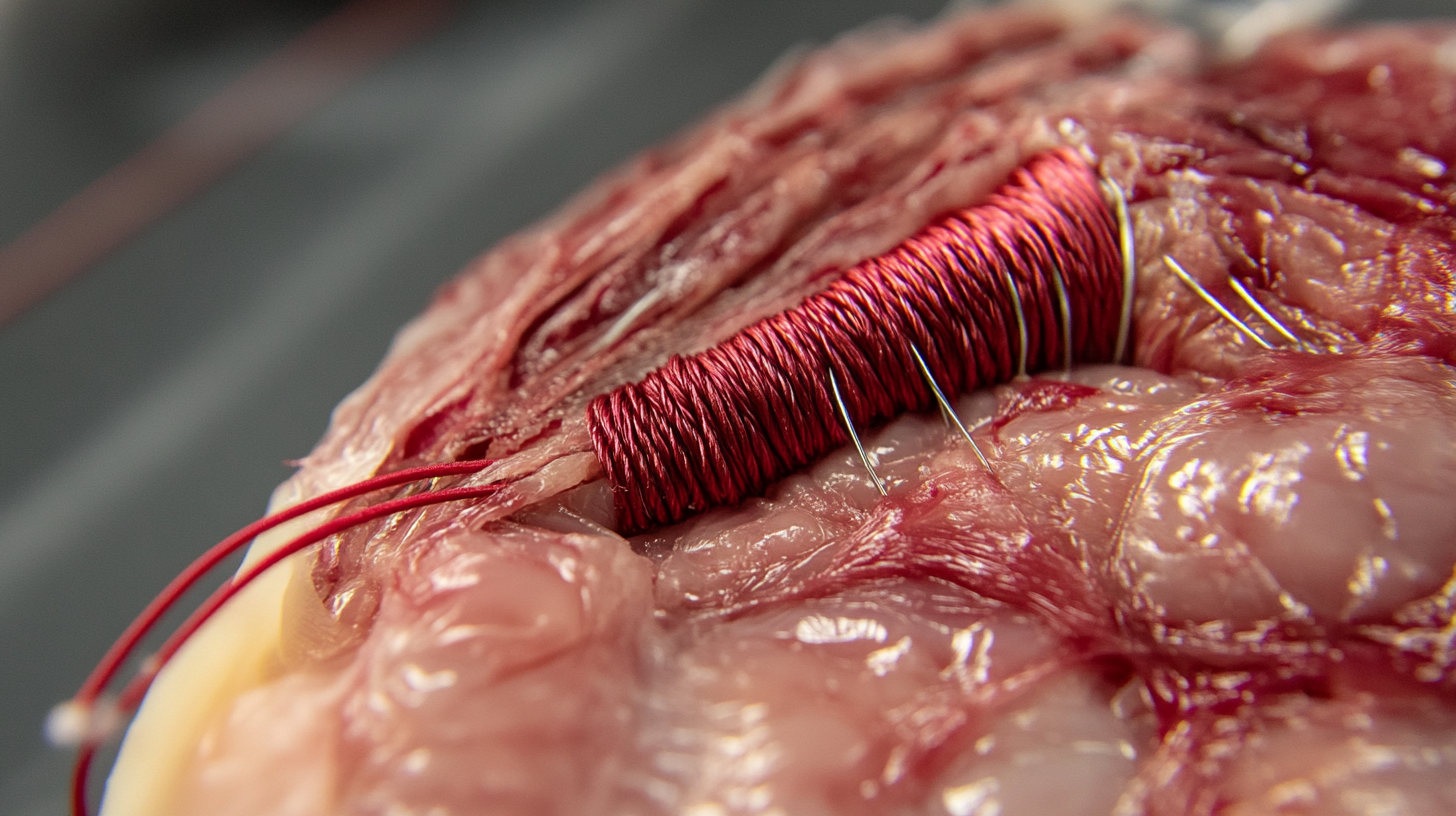

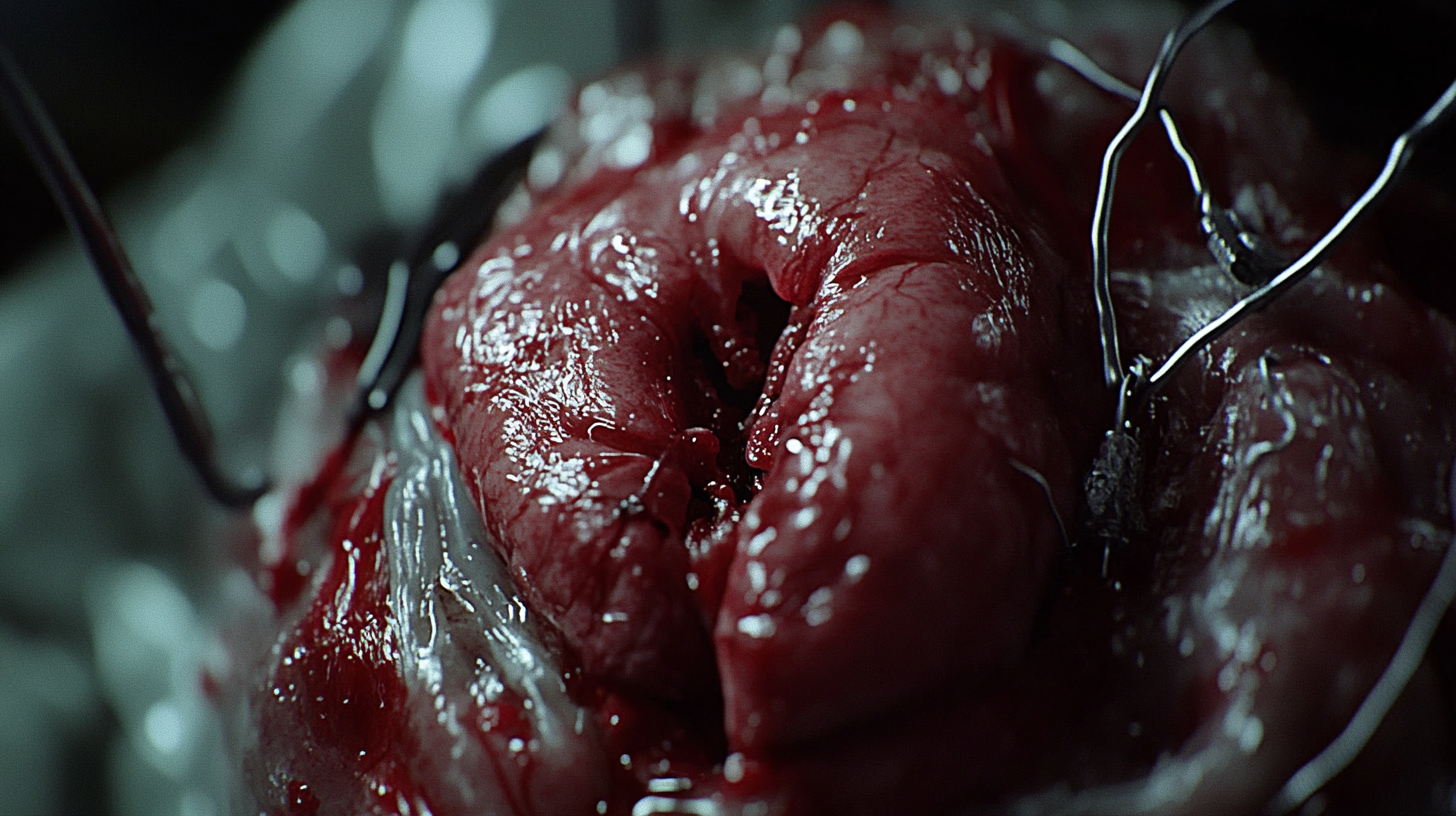

One crucial aspect of quality control is the materiaI sourcing process. High-quality PGA sutures should be manufactured using biocompatible materials that meet the FDA's guidelines for medical devices. Suppliers should demonstrate their commitment to quality by providing certificates of analysis for raw materials and detailed documentation of their production processes. Furthermore, manufacturers should engage in regular audits and inspections to ensure adherence to best practices, significantly reducing the likelihood of defects and enhancing patient safety.

Additionally, effective suppliers often implement advanced quality control techniques, such as statistical process control (SPC) and failure mode effects analysis (FMEA). These methodologies enable suppliers to identify potential issues in the manufacturing process before they affect the final product. Industry reports indicate that companies employing rigorous quality control measures can reduce product defects by up to 30%, directly influencing the cost effectiveness and reliability of their PGA sutures in clinical applications. Evaluating these processes can provide crucial insight into a supplier's capability to deliver high-quality sutures consistently.

Building Long-term Relationships with Trusted Suppliers

Building long-term relationships with trusted suppliers is essential for companies seeking stability and reliability in their supply chains. Recent studies highlight that organizations can significantly minimize supply chain risks by engaging suppliers as true partners rather than mere vendors. This approach fosters transparency, which is critical for establishing trust. Specifically, a strategic sourcing framework that emphasizes the overall value of supplier relationships over simple cost considerations can lead to more resilient supply chains.

The pandemic has underscored the fragility of many supplier relationships, revealing that businesses must go beyond mere trust. A recent survey indicated that 68% of companies recognized the need for more transparent communication with their suppliers to enhance collaboration and efficiency. By sharing expectations openly and committing to mutual goals, organizations can create a foundation of trust that leads to a more collaborative environment. As trust builds, suppliers are more likely to provide flexibility and responsiveness, crucial for adapting to unforeseen challenges.

To further improve supplier relationships, companies should adopt a mindset of shared success. According to industry experts, fostering an inclusive culture where suppliers are viewed as integral parts of the business can yield substantial benefits. This includes involving suppliers in strategic planning discussions, which can enhance innovation and align objectives for the long term. By doing so, organizations not only strengthen their supply chains but also cultivate loyalty and respect, ultimately enhancing their competitive edge in the market.