- Home

- Products

- Services

- Product concept development

- Engineering

- Design for manufacturability

- Regulatory services

Read more - Material selection and formulation

- Prototyping

- Testing and validation

Read more - Production process development

- Custom tooling

- Manufacturing

- Finishing operations

- Assembly

- Packaging

- Private labeling

- Sterilization

Read more

- Resources

- Careers

- Search

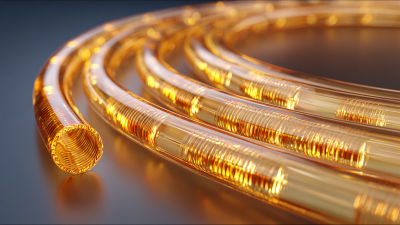

Unlocking the Benefits of Fep Heat Shrink Tubing for Your Next Project

Fep Heat Shrink Tubing has emerged as a game-changer in various industrial applications, offering unmatched advantages in insulation, protection, and flexibility. According to a recent market analysis by Grand View Research, the global heat shrink tubing market is projected to reach USD 2.9 billion by 2025, driven by increasing demand across sectors such as automotive, aerospace, and electronics.

Fep Heat Shrink Tubing, specifically, is praised for its outstanding chemical resistance and ability to withstand extreme temperatures, with operating ranges often exceeding 200°C. This high-performance solution not only enhances the longevity and reliability of electrical connections but also simplifies assembly processes. As industries continue to prioritize efficiency and safety, understanding the benefits of Fep Heat Shrink Tubing becomes crucial for professionals looking to optimize their next project.

Fep Heat Shrink Tubing, specifically, is praised for its outstanding chemical resistance and ability to withstand extreme temperatures, with operating ranges often exceeding 200°C. This high-performance solution not only enhances the longevity and reliability of electrical connections but also simplifies assembly processes. As industries continue to prioritize efficiency and safety, understanding the benefits of Fep Heat Shrink Tubing becomes crucial for professionals looking to optimize their next project.

Understanding FEP Heat Shrink Tubing: What Makes It Unique

FEP heat shrink tubing has become essential in the medical device industry due to its unique properties. This fluoropolymer is known for its exceptional thermal stability, chemical resistance, and low friction characteristics, making it ideal for applications requiring precision and reliability. Given the rapid innovations in the tubing sector, manufacturers are increasingly integrating FEP heat shrink tubing into their products, thus enhancing performance and functionality.

One standout benefit of using FEP is its ability to maintain its shape and integrity even under extreme conditions. According to recent market reports, the demand for fluoropolymer tubing is expected to grow significantly, reflecting a trend toward more specialized medical devices. Manufacturers can take advantage of these properties while also streamlining their supply chains by utilizing peelable heat shrink tubing, which simplifies the manufacturing process and reduces waste.

**Tips:** When selecting FEP heat shrink tubing for your project, consider factors such as the specific environmental conditions it will be exposed to and the compatibility with the materials used in your device. Ensuring these align will lead to better durability and performance. Additionally, check for any new innovations in the market that may offer enhanced features tailored to your needs; staying updated can give you a competitive edge.

Unlocking the Benefits of Fep Heat Shrink Tubing for Your Next Project

| Feature | Description | Benefits |

|---|---|---|

| Material Composition | FEP (Fluorinated Ethylene Propylene) is a type of fluoropolymer. | High chemical resistance, ideal for harsh environments. |

| Temperature Range | Operates effectively in temperatures from -200°C to 200°C. | Versatile for a wide range of applications. |

| Shrink Ratio | Typically 2:1 or 3:1 depending on the product. | Allows for snug fitting over components. |

| Electrical Insulation | Excellent dielectric properties. | Provides reliable insulation for electrical applications. |

| UV Resistance | Resistant to ultraviolet light and degradation. | Increases longevity in outdoor applications. |

| Application Areas | Used in automotive, electronics, and medical devices. | Versatile for various industries. |

Key Advantages of Using FEP Heat Shrink Tubing in Various Applications

FEP heat shrink tubing offers numerous advantages that make it an ideal choice for a wide array of applications. One of the key benefits is its exceptional chemical resistance, allowing for use in environments where exposure to harsh substances is commonplace. This attribute ensures that the tubing maintains its integrity and performance, making it suitable for industries such as electronics, automotive, and telecommunications. Furthermore, FEP’s high-temperature tolerance allows it to perform reliably in extreme conditions, which is essential for components subjected to heat or potential thermal stress.

In addition to its durability, FEP heat shrink tubing is also known for its excellent electrical insulation properties. With a low dielectric constant and high dielectric strength, it is highly effective in preventing electrical arcing and ensures the safety of sensitive electronic components. As industries increasingly shift towards high-speed data communication and renewable energy applications, the demand for reliable, high-performance materials like FEP heat shrink tubing is bound to grow, proving essential for projects that require precision and resilience in their materials.

Unlocking the Benefits of FEP Heat Shrink Tubing for Your Next Project

How FEP Heat Shrink Tubing Improves Durability and Performance

FEP heat shrink tubing is rapidly gaining popularity in various industries due to its exceptional durability and performance-enhancing properties. Unlike standard heat shrink materials, FEP exhibits outstanding resistance to harsh chemicals and extreme temperatures, making it an ideal choice for applications in environments where reliability is paramount. This fluoropolymer material not only shrinks to fit snugly around cables and connectors but also provides a robust barrier against moisture, dust, and mechanical stress.

FEP heat shrink tubing is rapidly gaining popularity in various industries due to its exceptional durability and performance-enhancing properties. Unlike standard heat shrink materials, FEP exhibits outstanding resistance to harsh chemicals and extreme temperatures, making it an ideal choice for applications in environments where reliability is paramount. This fluoropolymer material not only shrinks to fit snugly around cables and connectors but also provides a robust barrier against moisture, dust, and mechanical stress.

Moreover, FEP heat shrink tubing contributes to improved performance by ensuring optimal insulation and preventing signal loss in electronic components. Its exceptional dielectric strength and low friction properties further enhance the performance of electrical assemblies, allowing for greater efficiency in data transmission. As industries continue to prioritize robust and reliable materials, the rise in demand for FEP heat shrink tubing underscores its importance in modern engineering solutions, paving the way for innovative applications in sectors ranging from telecommunications to aerospace.

Choosing the Right FEP Heat Shrink Tubing for Your Specific Needs

When selecting the right FEP heat shrink tubing for your project, it’s essential to consider specific requirements such as temperature resistance, chemical compatibility, and the intended application. FEP (Fluorinated Ethylene Propylene) is renowned for its exceptional properties, including high-temperature durability and resistance to harsh chemicals, making it a top choice in industries such as automotive, aerospace, and electronics. According to recent industry reports, the global fluoropolymer tubing market is projected to grow at a CAGR of 5.1% from 2023 to 2030, highlighting the increasing demand for specialized materials like FEP in various applications.

Tips: When choosing FEP heat shrink tubing, ensure you assess the temperature ranges it can withstand and the dimensions that best fit your components. Additionally, consider whether you require a single lumen or multi-lumen design based on your project's complexity. Properly fitting tubing can streamline assembly and enhance the overall performance of your product.

Furthermore, understanding the specific environment where the tubing will be utilized is crucial. For instance, in applications exposed to aggressive chemicals or extreme conditions, FEP stands out as an ideal option compared to other polymers. Manufacturers are increasingly offering customized solutions tailored to unique project needs, which can significantly enhance the efficiency and effectiveness of your designs.

Practical Tips for Implementing FEP Heat Shrink Tubing in Your Projects

FEP heat shrink tubing offers a wide range of benefits that can enhance the performance and durability of your projects. When considering its implementation, it’s essential to evaluate the specific requirements of your application. Start by assessing factors such as temperature resistance, chemical exposure, and electrical insulation needs. FEP tubing can withstand extreme temperatures and harsh chemicals, making it an ideal choice for industrial and outdoor applications.

To effectively use FEP heat shrink tubing, ensure that you measure the components that need protection accurately. Cut the tubing to the required length, leaving enough margin for proper shrinkage. It is advisable to use a heat gun for even and controlled shrinking, which will prevent damage to sensitive components. Additionally, consider the use of colors or labels on the tubing to easily identify different wires or components in complex setups. By following these practical tips, you can harness the excellent properties of FEP heat shrink tubing, improving both the safety and functionality of your projects.

Related Posts

-

Common Issues with Best Fep Heat Shrink Tubing and Their Impact on Performance

-

Market Trends for Best Fep Heat Shrink Tubing and Future Outlook Towards 2025

-

Ultimate Guide to Choosing the Best Fep Heat Shrink Tubing for Your Needs

-

In-Depth Technical Specifications of PTFE Liners: A Comprehensive Guide

-

What is Polyimide Tubing? Unveiling Properties, Applications, and Market Trends in 2023

-

Exploring the Future of Best Medical Balloons in 2025 Technology Trends